To understand how reservoir simulation leads to the prediction of reservoir behavior, you first need to understand what reservoir simulation is.

What is Reservoir Simulation?

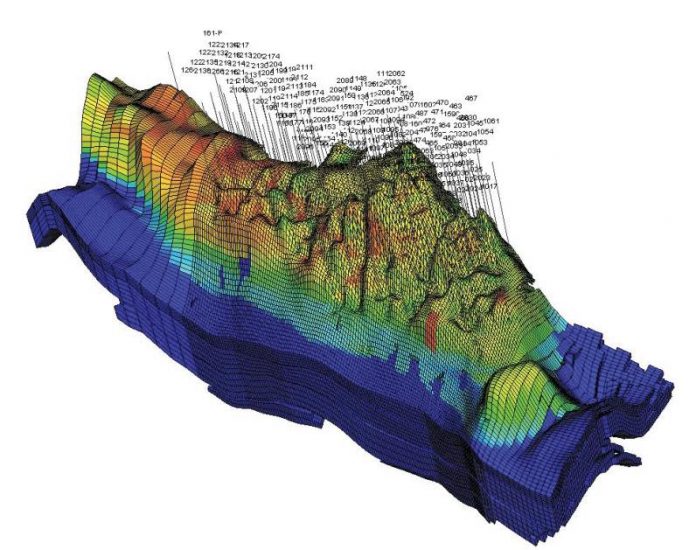

It is an area of reservoir engineering which combines different disciplines such as physics, computer programming, and mathematics to a reservoir model to predict and analyze the fluid behavior in a reservoir over time. In short it can be defined as the process of imitating the fluid flow behavior in oil reservoir systems such as reservoir rock and fluids, surface, and subsurface facilities through mathematical and physical models. It’s a very effective tool for understanding the performance of the petroleum and gas reservoir under different strategies.

What reservoir simulation contains?

It consists of the following:

- A geological model containing a volumetric grid with cell/face properties explaining the spongy rock structure.

- A flow model explaining how fluids flow in a porous channel, mainly as a set of partial differential equations covering mass and volume conversation with closure relations.

- A well model sharing the in and outflow of the reservoir including a flow model within the wellbore.

When is reservoir simulation used?

It is mainly used for two main reasons:

- To help with operational and investment plans

- To mature development plans for new fields

In order to perform reservoir simulation, different complex case studies are carried out by the subject experts for preparing the simulation input data set. The simulation study includes different elements such as:

- Relevant Field History

- Forecast and Predictions based on the existing operational strategy

- Evaluating operative Scenarios

Purpose of Reservoir Simulation

Reservoir simulation is done to forecast field performance and recovery for different field development scenarios. This is further evaluated to understand the effects on the recovery of multiple operational conditions in addition to the comparison between the economics of different recovery methods.

The simulation method uses a 3D spatial approach. This method is more robust compared to the analogous, decline, type curve, or empirical methods as it shares dimensionality which the other methods are unable to do. This is the only prediction method which includes vertical and areal distributions of the non-uniform rock properties, rock-fluid properties, pressures, and saturations. It helps in assessing development alternatives that are accurately required for most ventures.

Today, reservoir simulation holds the importance of being the standard practice in the industry at all levels (forecast, facility, and field). The classic reservoir simulation allows multiphase flow simulation in heterogeneous reservoirs. It also includes variations of reservoir properties such as pay zone thickness, porosity, fluid-saturation, faults inclusion, and multiple wells. Whereas the modern reservoir simulator makes multi-stage fractures possible. Reservoir simulators are also combined with wellbore flow simulators to allow a wellhead pressure/flow rate. They are widely used to optimize the completion of good designs and to maximize well productivity and field production.

However when using a reservoir simulation model for forecasting and predictions of reservoir behavior, understand the uncertainties involved in this model. For example, if the geological model is not appropriate and does not offer quality data, then you can not get quality results from the reservoir simulation model even if the history match is perfect.

Reservoir simulation is not a new concept in the engineering industry. It has been in use for a long time by engineers using mathematical models and calculations. However, today the engineering calculations are digitized with the help of computers. Dynamic simulation software is available to do the job for you.

It also includes new features that make the study more detailed and helps in predicting much more accurate simulations. It also has become practical due to the widespread use of computers in this day and age. However, some engineers are required to solve complex mathematical expressions which are quite difficult to understand to fetch more details. This results in many engineers shying away from using these simulators. But as time goes on, this simulator software would be used more so the engineers need to be competent enough for understanding and operation simulation problems, dealing with input data and calculation of results.